Construction

All CB guitars feature:

|

All solid woods - no laminates or synthetic materials |

|

|

|

Hand-scalloped braces & tap-tuned tops |

|

|

|

Hand-shaped necks to customer's specifications |

|

|

|

Hand-crafted genuine bone nuts & saddles |

|

|

|

Genuine bone bridge pins |

|

|

|

Hand-rubbed Nitrocellulose Lacquer finishes |

|

|

|

Quality hardshell case |

|

|

|

Limited Lifetime Warranty |

Chris' craftsmanship

and attention to detail and tone quality assure you of the finest instruments available

today, and Chris' artistry and his eye for aesthetics assure that his

instruments will be as beautiful to the eye as they are pleasing to the ear.

The following pictures are meant to show you some of the

craftsmanship that goes into the creation of each CB guitar.

Click this link for sound

samples of CB instruments.

Click Here for Step-By-Step

Construction of a CB Model J

Chris' first step in constructing a CB Guitar is bending the

sides. Here Chris is removing a quilted Mahogany side from his

boiling trough. Boiling time varies by wood species and amount of

figure; typically, figured wood must be boiled for a longer period

of time to allow the wood to bend without cracking. Some species

require no boiling at all, only a short soaking.

(click picture for a larger version) |

|

Chris bends the side wood over a heated bending iron of his own

design & construction.

(click picture for a larger version) |

|

|

|

A steady hand and a practiced eye are required to bend the sides

without cracking the wood...

(click picture for a larger version) |

|

...and to achieve the closest possible fit to the body

form without twisting or distorting the wood.

(click picture for a larger version) |

|

|

|

Chris clamps the side wood into his hand-made body form.

Carefully bending the wood to closely fit the form eliminates the

possibility of the wood cracking while in the form.

(click picture for a larger version) |

|

The center spreader blocks lock the body into the form, and

hold the gentle curve of the waist area.

(click picture for a larger version) |

|

|

|

Adjustable clamps allow Chris to adjust the tension of the body

form as necessary.

(click picture for a larger version) |

|

The body will remain clamped in the form until it is able to

hold its shape on its own, without distortion. Clamping time

varies by wood species.

(click picture for a larger version) |

|

Chris assembles the body of an Indian Rosewood

"Herringbone" Cutaway. |

Guitar top awaiting tuning and scalloping of braces. |

|

All CB guitars feature hand-scalloped braces of select Sitka Spruce and

tap-tuned tops for maximum tonal response and volume. |

Chris hand-fabricates kerfed lining from Mahogany stock. |

|

Lining is glued to sides in body form. |

Back braces are located and glued in a gluing jig

fabricated by Chris. |

|

Chris clamps the guitar braces to the back in the

gluing jig. |

Indian Rosewood "Herringbone" Cutaway body in form. |

|

Indian Rosewood "Herringbone" Cutaway back awaiting

hand-shaping of braces, shown with body in form. All CB guitars feature

hand-shaped back braces of select Sitka Spruce. |

Front view of unfinished Mahogany "Herringbone" body. |

|

Rear view of unfinished Mahogany "Herringbone" body. |

Front view of unfinished Indian Rosewood "Herringbone" body. |

|

Rear view of unfinished Indian Rosewood "Herringbone" body. |

All CB guitars feature hand-fit dovetail neck joints. The dovetail neck

joint, while harder to accomplish properly than modern

"shortcuts", is still the finest method ever devised for neck

attachment. |

|

The dovetail neck joint allows for maximum tone transmission from neck

to body, maximum strength, optimum playing action, and ease of future neck

repairs. |

In

order to introduce an adjustable truss rod that adjusts neck tension

through the sound hole, some manufacturers drill a hole through the

transverse brace that lies underneath the fretboard extension. This

weakens this major brace in its most critical area, and leads to problems

such as top distortion and neck block displacement. Beware of guitars

featuring this type of neck adjustment! |

|

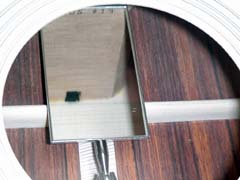

This picture, taken with a mirror looking at the underside of the top

at the neck block through the sound hole, shows Chris' solution to this

problem. Rather than drill through the transverse brace to allow access to

the truss rod adjustment nut, all CB guitars feature an adjustment nut

that is accessible through the end of the neck block by simply reaching

inside the guitar behind the transverse brace. This allows for

easily-accessible neck adjustment while maintaining the structural

integrity of the guitar. |

"Standard" acoustic guitar

cutaways used by other makers are typically

just that: the upper treble bout of the

guitar is simply removed to allow more

access to the upper frets. Most makers do

not take the extra care to follow the angle

of the heel to the back of the guitar. This

results in an unsightly "wedge" of

wood by the treble side of the neck heel

that really gets in the way when playing in

the higher positions. |

|

The CB cutaway follows the angle of the

neck heel to the back of the neck for

easier access and a better appearance.

This requires a great deal of work, as a

"compound radius" is required,

but the playability and beauty of this

cutaway is worth the extra effort. Because

of this compound radius, CB cutaways are a

"Florentine" (sharp) design

rather than a "Venetian"

(rounded) design. |

Chris hard at work, cutting pearl for inlays. |

|

All inlays are hand-cut and hand-inletted by Chris. |

Chris buffing the finish of a

CB-ROM. |

|

Final

cleaning & setup of a CB-ROM. |

Last modified: November 28, 2015

|

![]()