Construction of a CB Model J

Page 3

Click on the

pictures for a larger version.

The rosette is inlaid into the

top. |

|

Chris uses a blade to scrape

the rosette even with the top. |

The binding procedure used for the top is

repeated around the back. |

|

|

Detail shot of peghead

shows completed inlays.

Inner purfling for fretboard

is shown, with space left

for outer fretboard binding.

Also visible are the pilot

marks for tuning machine

holes, and the centerline

mark for the fretboard.

|

|

The outer binding for the

fretboard is applied after

the inner purfling and frets

are installed. Note the

depth of extra binding

material left above the

frets, which will be leveled

and dressed to the frets.

|

Chris fits the small piece of binding

at the end of the fretboard. |

|

Once the epoxy for the

fretboard binding sets, Chris

uses a blade to scrape the

binding material even with the

tops of the frets. |

A small file is

then used to level

the binding to the

fretboard between

the frets, leaving

binding material

at the end of each

fret. |

|

Chris finishes

the fretboard

binding material

to the end of each

fret, rather than

dress the fret

ends over the edge

of the binding as

most makers do.

This not only

gives a much nicer

appearance, but it

also makes for a

much smoother

feel. Frets can

still be easily

replaced when

necessary without

damaging the

binding. |

Detail shot of the underside of the

fretboard at the neck dovetail shows

Chris' adjustable truss rod. |

|

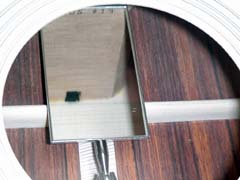

This picture, taken with a mirror looking at the underside of the top

at the neck block through the sound hole, shows access hole through the

neck block for truss rod adjustment. All CB guitars feature an adjustment nut

that is accessible through the end of the neck block by simply reaching

inside the guitar behind the transverse brace underneath the end of the

fretboard. This allows for

easily-accessible neck adjustment while maintaining the structural

integrity of the guitar by not drilling the transverse brace for truss rod

access as some manufacturers do, which

weakens the top at this critical stress

area. |

Detail shot of neck heel shows

the adjustable truss rod, neck

dovetail and heel cap inlay. |

|

A dovetail is cut into the neck

block to receive the neck

dovetail. Great care must be taken

to insure that the neck dovetail

exactly fits this body dovetail,

and that the neck angle is set

correctly, as there is no margin

for error here. Also shown is the

notch for the adjustable truss

rod, and the routed ledges for top

binding and purfling are apparent. |

This picture of

the neck and body dovetails shown

together gives an idea how the

parts fit. While the traditional

dovetail neck joint is no longer

used by some of the major

manufacturers due to the

hand-fitting required, it is still

the best method for achieving a

strong, stable joint allowing

maximum sound transmission from

neck to body. |

Continue

to Next Page

Last modified: November 28, 2015

|

![]()